Company History

1931

Based on the conclusions of the Special Commission, which worked on the territory of Ukraine searching for an appropriate site for the construction of the world's most powerful full-cycle metallurgical combine with pipe-rolling production, the USSR's Supreme Soviet of the National Economy made a decision on launching the construction in Nikopol.

1931

Preliminary works & launch of the construction process.

1932

The session of the Gipromez Technical Council approved the draft design of Nikopol Pipe Plant with a capacity of 410 thousand tons of pipes and staff of 13,500 persons.

1935

The rolling mill was put into operation, and the first pipes were produced. Until May 1, 50 thousand tons of pipes were rolled.

1935

The Nikopol plant appeared on the list of the USSR operating enterprises .

Petr Petrovich Brachko

The first director of the plant.

1939

Production of pipes exceeded the volume of pipe and tube production in tsarist Russia (1913) by more than one third.

Alexei Matveyevich Astakhov

Director of the plant from 1939 to 1941. He was awarded the Order of the Red Banner of Labor. He supervised the evacuation of the plant in wartime.

1939

At the beginning of the Second World War, the main rolling and machine equipment of the plant, its workers, engineering and technical experts as well as students of the Plant Vocational School were evacuated to the Urals, where the construction of factory workshops was launched.

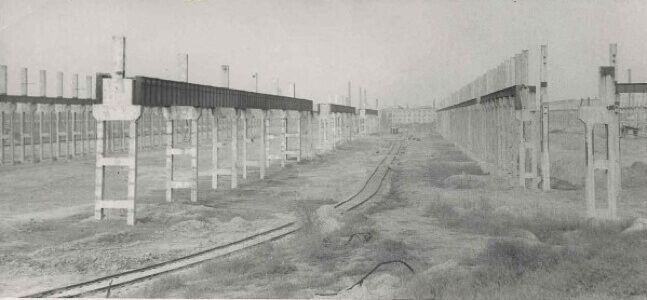

1944

The Plant restoration started.

1945

Due to efforts of workers and technical staff, the first stage of restoration came to the end. In the Rolling Shop No 2, the construction of a new unique mill "400", the largest in the USSR and Europe, started.

1947

The Rolling Shop No 2 with the mill "350" started its operation.

Nikolay Alexandrovich Tikhonov

Director of the plant from July 1947 to December 1950.

1950

The tube rolling mill "140" in the Rolling Shop No 1 was mounted

1955

The Electric Welding Shop and Pipe-casting Shop produced first tubes

Pavel Abramovich Trubchenko

chief engineer of the plant

1956

The Shop for finishing pipes intended for geological exploration was put into operation.

1958

The USSR's first shop for production of extruded steel pipes was commissioned.

1959

Cold rolling technology development. The Cold-drawing Shop No 2 (CS-2), currently one of CENTRAVIS structural units, started its operation and produced the first cold-finished tube.

1961

The Hot-extrusion Shop No 4 (HS-4), currently a hot extrusion production area of CENTRAVIS PRODUCTION UKRAINE PJSC, was commissioned.

1970

The Cold-drawing Shop No 7 with a "30-102" mill for continuous rolling started its operation.

1976

The Cold-drawing Shop No 4 was put into operation.

1984

The Cold-drawing Shop No 5 was commissioned.

Contemporary History

1991

Dnepropetrovsk-based commercial and manufacturing enterprise UVIS LLC started its work.

Vasily Atanasov

One of the founders and shareholder of CENTRAVIS. Since 1992, he held managerial positions at the family enterprise of PKP "UVIS".

2000

Dnepropetrovsk-based commercial and manufacturing enterprise UVIS LLC initiated privatization of the Nikopol Yuzhnotrubny Plant facilities, which resulted in establishing of Nikopol Plant of Stainless Steel Tubes CJSC (NSTM) on the basis of CS-4 and HS-2.

2006

Shareholders of NSTM CJSC made a decision on incorporating facilities of Nikopol Stainless Tube Mill, currently known as CENTRAVIS PRODUCTION UKRAINE PJSC with service companies and sales offices of UVIS Group.

2007

CENTRAVIS as a new world-wide steel manufacturer was established due to business integration in 2007. Official presentation of the new brand took place on November 6, 2007 during the Stainless Steel World Exhibition, Maastricht (the Netherlands).

2008

The program for upgrading the CENTRAVIS production facilities with the total value of over $ 130 million was initiated. A new, highly-efficient extrusion line comprising equipment of the best German manufacturers SMS MEER and IAS was launched within the following four years. New KPW-25 cold-rolling mills, a U-bending machine, a new continuous finishing line for HEX tubes production as well as up-to-date quality control system were put into operation in the Cold-drawing shop.

Yuriy Atanasov

Member of the Board of Directors, shareholder, CEO since September 22, 2009

2012

After renewal of production volumes to the pre-crisis level in 2011, CENTRAVIS set its own production record by shipping over 18,000 tons of finished products in 2012.

2014

Launch of the large-scale World Class Production project. This is a comprehensive platform to implement CENTRAVIS transformation into a global, competitive enterprise with efficient business processes, consistently high product quality, minimal risks and optimal costs at all the stages of the production process.

2017

Continuous expansion of the Company's presence in the world markets. CENTRAVIS opens a representative office in the UAE. The Office in the region will enable more active dealing with the customers and increased export volumes of finished products.

2022

Centravis continues to work during the war. Despite the complicated circumstances in Nikopol, where the company's industrial facilities are located, production is provided with billets and all necessary materials. Also there is work on the implementation of the plan for the expansion of the enterprise.