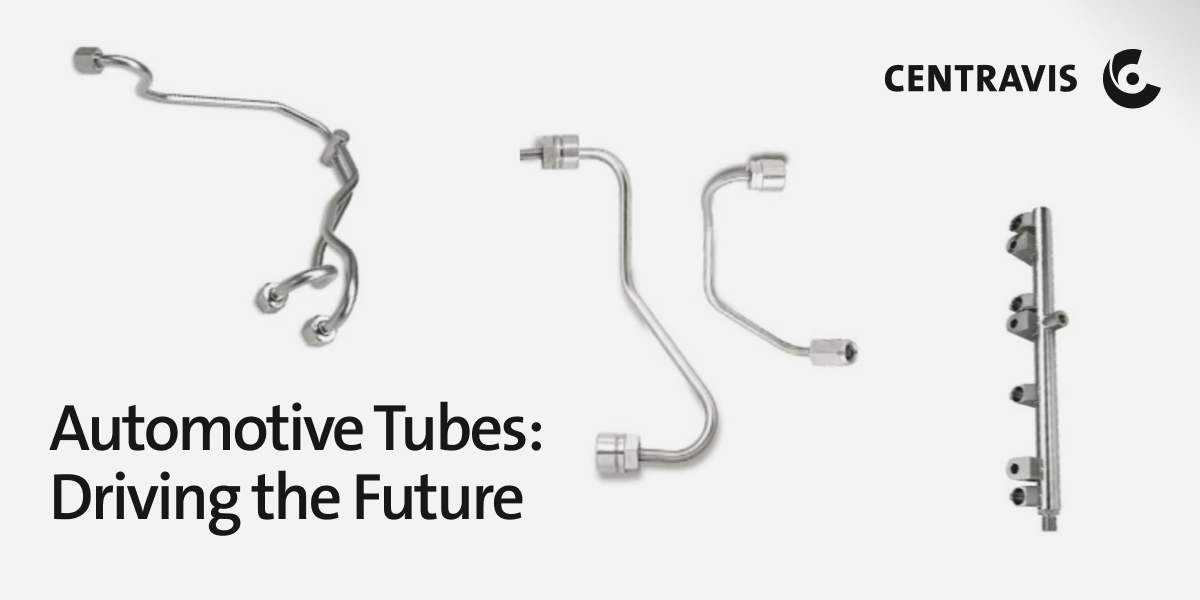

In the rapidly evolving automotive industry, the demand for high-quality components that ensure safety, efficiency, and sustainability is more critical than ever. Among these components, automotive tubes play a pivotal role in the performance and reliability of modern vehicles.

The Integral Role of Automotive Tubes in Modern Vehicles

Automotive tubes are essential components used in various vehicle systems, including fuel injection, exhaust, braking, and cooling systems. Their reliability and performance directly impact the overall safety and efficiency of a vehicle. As vehicles become more advanced, the requirements for these tubes have become increasingly stringent, necessitating precision engineering and high-quality materials.

Manufacturers must focus on innovation, quality, and collaboration to meet the evolving demands of the automotive industry. By embracing new materials, advanced manufacturing processes, and sustainable practices, industry can drive the future of transportation, delivering vehicles that meet the highest standards of performance and environmental responsibility.

And Centravis Team, as experts in the production of high-quality automotive tubes, is committed to supporting the industry’s advancement through innovation and excellence.

Market Analysis & Outlook

Global Automotive Tubes Market

According to research by Market Research Intellect, the global automotive tubes market is projected to experience significant growth in the coming years. Rising demand for lighter vehicles, stricter emission regulations, and the expanding role of advanced propulsion systems (e.g., hydrogen fuel cells) are key factors driving this trend. The report emphasizes how suppliers and manufacturers are increasingly investing in new alloys and production techniques to cater to the automotive sector’s push for higher performance and sustainability.

Driving Efficiency for Next-Gen Vehicles

Additional insights from Market Research Intellect indicate that advanced automotive tubes are central to achieving next-generation vehicle efficiency. As automakers introduce turbocharging, direct injection, and alternative fuel systems, the demand for tubes with higher strength and corrosion resistance grows. This analytical view underscores the importance of both research and strategic partnerships in developing the sophisticated tubing solutions necessary to meet evolving industry needs.

Challenges and Technological Advancements

1. Meeting Demands for High Performance

The integration of advanced systems like direct fuel injection and turbocharging has increased the demand for specialized tubing that can withstand higher pressures and temperatures.

Centravis is ready to meet the demand with not only austenitic steel grades but also Duplex and Lean Duplex Stainless Steels to provide higher strength and resistance to stress corrosion cracking. These materials ensure reliability even in the most demanding conditions, offering automotive manufacturers the flexibility to design cutting-edge systems without compromising durability.

2. Supporting Environmental Sustainability

Environmental concerns are reshaping the automotive industry, with a significant shift towards sustainable practices and technologies. Hydrogen Fuel Cell as well as Hydrogen Internal Combustion engines are forefront of alternative propulsion systems aimed at achieving a green future and adhering to zero-emissions policies.

Centravis supports this transition with its advanced H2Fit production line, delivering hydrogen-compatible products with significant resistance to corrosion and hydrogen embrittlement, alongside exceptional mechanical properties. This ensures that our solutions align with global sustainability goals while maintaining superior performance.

3. Enhancing Efficiency Through Lightweight Materials

Beyond technological advancements, cost-saving initiatives remain a critical expectation from automotive market players. Using lightweight materials is a key strategy for improving fuel efficiency and reducing emissions.

Centravis offers innovative solutions such as advanced high-strength steels, including Balev Steel, a lightweight stainless steel that combines high strength and corrosion resistance with lower density. These material enables the production of thinner-walled tubing without compromising performance, supporting vehicle weight reduction, enhanced fuel efficiency, and reduced environmental impact. Balev Steel innovation empowers manufacturers to meet stringent regulatory standards and customer expectations.

Conclusion and Future Outlook

The automotive industry stands at the intersection of technological innovation, environmental responsibility, and heightened performance demands. Automotive tubes, as essential components within advanced vehicle systems, must continue evolving in terms of material composition, design, and manufacturing processes to keep pace with these ever-changing needs.

From high-performance steel grades for turbocharged engines to hydrogen-ready tubing solutions for alternative propulsion methods and lightweight developments that reduce emissions, the sector as a whole is devoted to shaping a new generation of transportation. By focusing on strategic collaboration, research, and continuous improvement, automotive tubes will become even more reliable, efficient, and eco-friendly.

As the industry progresses, further developments in smart materials, digital production methods, and comprehensive testing will push boundaries—leading to safer roads, a cleaner environment, and a sustainable global future. This ongoing evolution in automotive tube production paves the way for innovations that will truly drive the future of mobility.