CENTRAVIS is a leading global supplier of high-quality solutions in seamless stainless steel tubes segment taking the 1st place in the CIS, the 3rd place in the EU and the 9th place in the world on sales volumes with total share of 3.6%.

Applications

Unlike carbon tubes or stainless welded tubes seamless tubes are applied in more harsh environments and are supplied to a variety of industries with corrosive media, high and ultrahigh temperatures & pressures, other aggressive conditions. Key application areas of Centravis products are chemical and petrochemical engineering, mechanical engineering and power generation, including nuclear.

- Heat-exchanger tubes

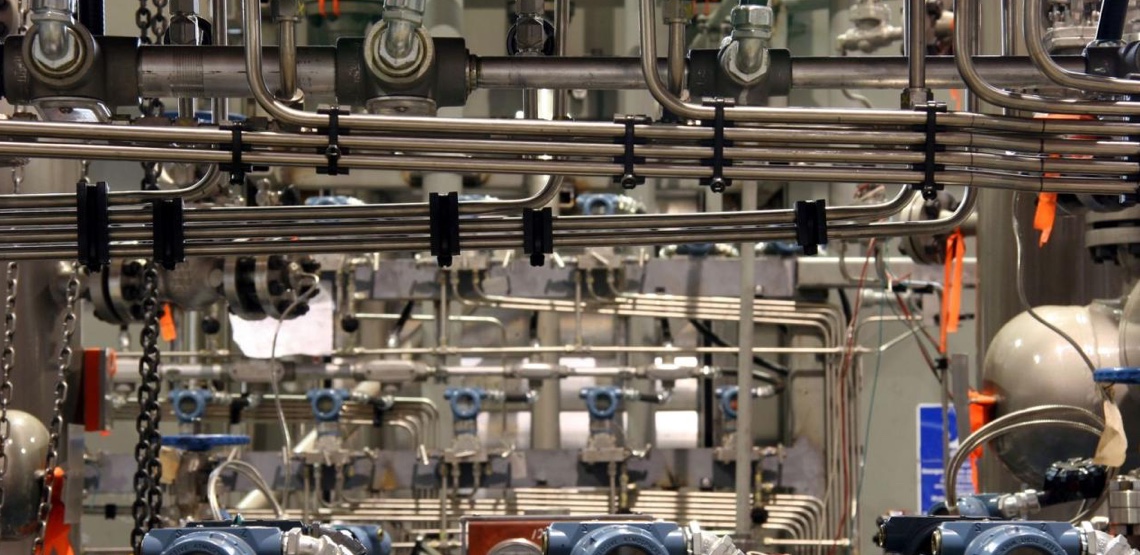

- Instrumentation tubes

- Boiler tubes

- Furnace tubes

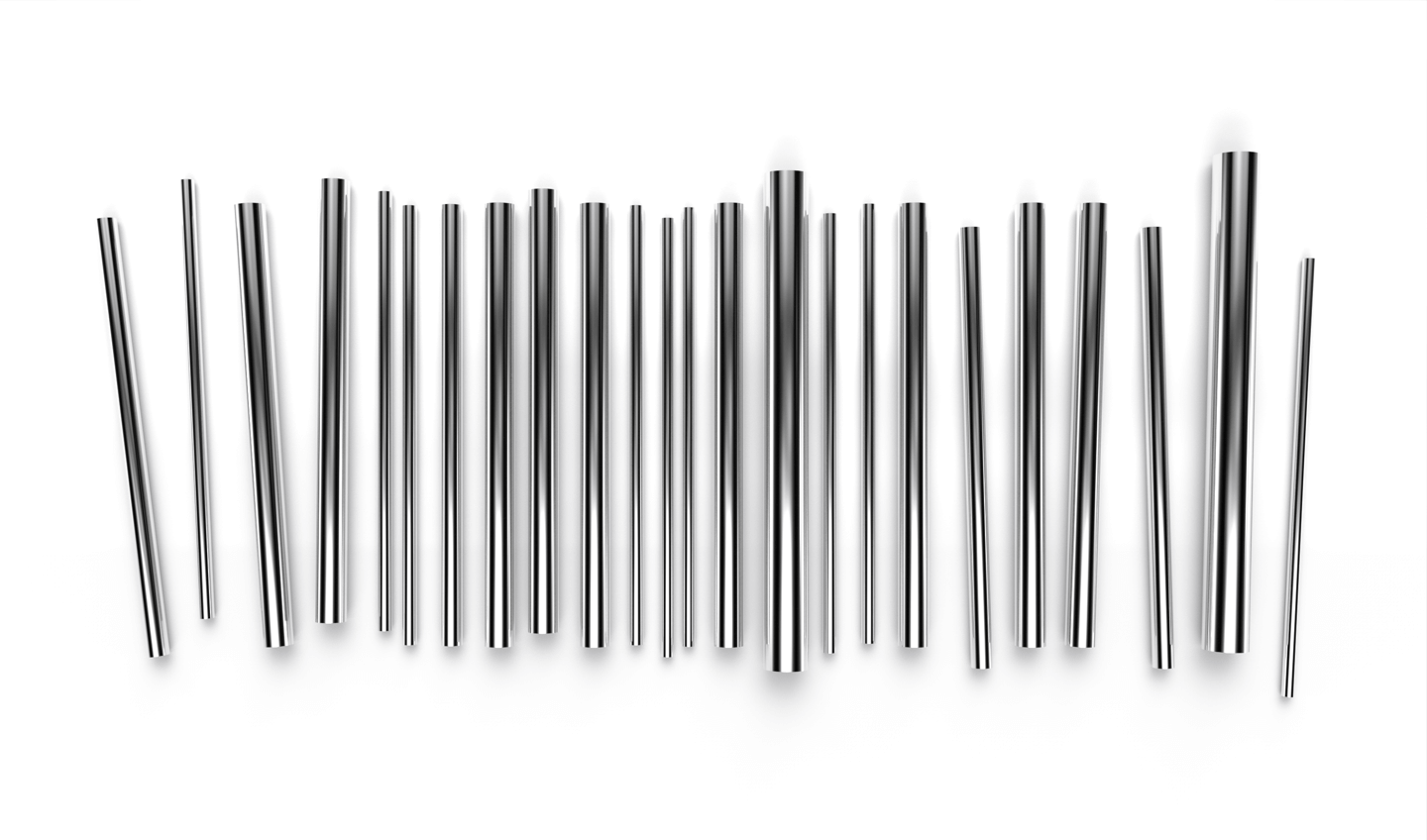

- Hollow bars

- Automotive tubes

- General tubes & pipes

- Nuclear tubes

- H2FIT tubes

Heat-exchanger tubes are designed for heat transfer and mostly applied in the processes like heating, cooling, ventilation, condensation and evaporation.

Heat-exchanger tubes are used in the following types of equipment: shell & tube heat exchangers, plate & frame heat exchangers, cooling towers, air coolers and others. Main industries of heat-exchanger tubes application are chemical & petrochemical, power generation (including nuclear), oil & gas and others (food&beverage, pulp&parer, transportation, etc.).

Instrumentation tubes are widely used for automotive industry.

Instrumentation tubes are widely used for hydraulic & pneumatic control systems, fuel supply lines, pressure sensors lines for automotive industry; for onshore control panels, topside processing facilities and subsea manifolds in oil and gas industry; high purity tubes for semiconductor industry, fuel rods, control tubes for advanced engineering; cooling circuits, brake cylinders for automotive industry.

Boiler tubes are applied in thermal power-generation and heating as a part of tubing components of utility and industrial boilers.

Boiler tubes in power-generation are used only for utility boilers to generate steam for electricity production. Boilers for industrial applications produce steam or hot water for process applications for various industries – biomass firing (fluidized bed boilers), heating, pulp and paper industry (recovery boilers), waste to energy plants, various chemical processes. Boilers are used for different combustion systems (conventional coal, oil and gas) and usually boiler tubes withstand high pressure and high temperature conditions.

Boiler tubes for nuclear power-generation are used within secondary cycle of nuclear power stations and are a tube components of a steam generation boiler. Special safety requirements are applied to nuclear boiler tubes, which is due to critical application area.

Furnace or heater tubes are mainly used in petrochemical industry as process tubes in cracking furnaces for refineries and ethylene\propylene plants.

Oil refinery cracking processes allow the production of «light» products such as liquefied petroleum gas (LPG). In a typical ethylene furnace the pyrolysis reaction is endothermic. For this reason, furnace tube material must be suitable to accommodate the high process temperature

Hollow bar – also called the seamless mechanical tubing, – is a tubular product made with properties and characteristics suitable for subsequent transformation into a numerous cylindrical components and hollow products for different engineering purposes.

Applications of hollow bar include aerospace, electronics, medical, military, food processing, transportation, chemical and petrochemical industry. Hollow bars are widely used in general engineering industry.

Seamless stainless steel tubes are widely used for automotive industry. But the most common application is as a part of fuel supply systems in GDI (Gasoline Direct Injection) engines.

General tubes & pipes are used as piping components or line pipes for variety of industries: chemical\petrochemical, oil&gas, power generation, processing, food&drink, metallurgy, and others.

In nuclear industry the tubes are used as parts of primary and secondary circuits of nuclear power station facilities. Depending on application and specific requirements, the tubes can be divided into three sub-segments – steam-generating, heat-exchanging tubes and pipelines.

Optimize Performance and Sustainability with CENTRAVIS's H2FIT Tubing Solutions

At CENTRAVIS, we are committed to environmental responsibility and this value is at the core of our

sales strategy and evolutionary path.

We are constantly working on projects, collectively known as H2FIT, that use hydrogen-friendly

materials for high and ultra-high pressure industries.

We work closely with our customers to expand our expertise in hydrogen applications and develop

the next generation of environmentally friendly steel products. In addition to traditional steel grades

such as TP316L/1.4404, TP316L/1.4435, and TP316 with elevated nickel content, we offer other

patented technologies for the production of H2FIT tubes.

These technologies not only optimize the service life in hydrogen applications (production, storage,

and usage), but also allow to reduce the weight of the final product, giving designers an added benefit.

By using H2FIT tubes, our customers can reap great economic benefits while contributing to the

reduction of carbon dioxide emissions resulting from steel production.

Not only do our customers receive high-quality products, but they also become part of the process of

making our planet safer and cleaner. If you are looking for stainless steel solutions for your H2

application, CENTRAVIS can help you make the right choice.